| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Shangle

Model Number : 12.7

Certification : PED,IS09001

Place of Origin : CHINA

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, T/T

Supply Ability : 500TONS/30DAYS

Delivery Time : 30DAYS

Packaging Details : Woven Packing

Material : 304 ,304L 310 321 316 316L

Standard : AISI, ASTM, DIN, EN, GB

Shape : SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80

Technique : Cold Draw

Application : Oil, Petroleum/Power

Package : Woven Packing

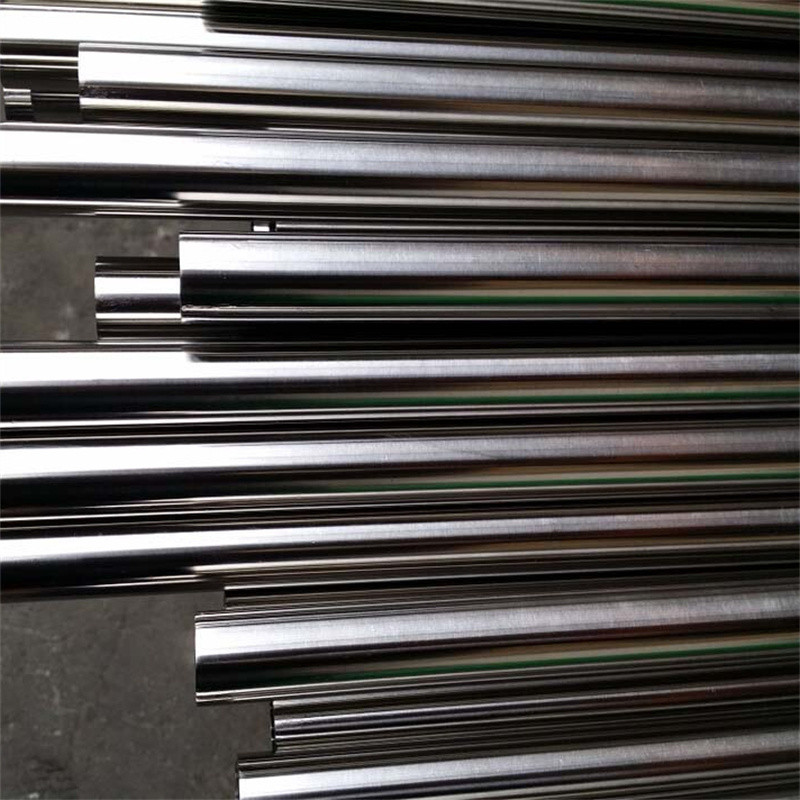

Bright Annealed Stainless Steel Tube EN10216-5 TC1 D4 / T3 1.4301 1.4307 1.4401 1.4404 , 1INCH BWG 16 20FEET

Characteristic: With cold press (mainly cold rolling), the gas protects heat treatment, with high precision:

ID:Ra≤0.4μm,OD:Ra≤0.8μm;Mainly for precision instrument, Hydraulic pressure system, exhaust gas

system etc.

Standard: ASTM/ASME A/SA213, A/SA269, DIN17458/17457, EN10216-5 D4 /T4 /10217-7. After negotiation, we can

supply pipe with customers’ requirement.

Material Grade: 1.4301,1.4307,1.4948, 1.4821, 1.4845, 1.4401, 1.4404, 1.4406, 1.4571, 1.4539, 1.4438, 1.4541, 1.4550, 1.4912, 1.4462, 1.4362, 1.4410, 1.4501 etc also ASTM, GOST, JIS grades available, other grade can also be provided after consulting with customers.

Size Range:Seamless Tube(OD: Φ6mm-Φ76mm WT: 0.15mm-4.0mm, Length:Max. 500M/pc)

Some of the quality tests carried out by us includes:

| Corrosion Test | Conducted only when specially requested by the client |

| Chemical Analysis | Test done as per required quality standards |

| Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test | To check any evidence of air leakage |

| Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

|

|

|

Main Test of ss sml tube :

EDDY CURRENT TEST EN 10249-3 E3H

US-TEST EN 10246-7 U3B

TENSILE TEST EN ISO 6892-1

FLATTENING TEST EN ISO 8492

DRIFT EXPENDING TEST EN ISO 8493

LEAK-PROOF TEST EN 10246-1

Application :

Air Cylinder Tubing,

Automotive fuel lines,

Heat Exchanger Tubing,

Hydraulic Cylinder Tubing,

Precision Mechanical Tubing,

Sanitary service,

Thermo couples

|

|

Bright Annealed Stainless Steel Tube EN10216-5 TC1 D4 / T3 1.4301 1.4307 1.4401 1.4404 , 1INCH BWG 16 20FEET Images |